In the fast-paced world of electrical work, it is crucial for electricians to prioritize safety at all times. From preventing electrical shocks to safeguarding against fires, understanding basic safety measures can mean the difference between a successful completion of a project and a potential disaster. This article aims to provide an insightful overview of the fundamental safety practices that every electrician should be aware of. So, fasten your seatbelts and get ready to enhance your safety know-how in the electrifying world of electrical work!

Understanding Basic Safety for Electricians

Introduction

When working with electricity, ensuring safety is paramount. Electricians play a crucial role in ensuring the proper functioning of electrical systems, installation, and repairs. However, the nature of their work exposes them to various hazards that can be potentially life-threatening. It is imperative for electricians to have a strong understanding of basic safety practices to safeguard themselves and others from potential accidents and injuries. This article aims to provide a comprehensive overview of basic safety for electricians, highlighting the importance of safety, electrical hazards, personal protective equipment (PPE), safety training, safe work practices, lockout/tagout procedures, emergency preparedness, working in hazardous environments, safety inspections, and continuous learning and improvement.

Importance of Basic Safety for Electricians

Electricians work with electricity, a powerful and potentially dangerous energy source. The importance of basic safety for electricians cannot be overstated. By adhering to safety practices, electricians significantly reduce the risk of accidents, injuries, and even fatalities. Additionally, following safety protocols ensures that work is completed efficiently, without compromising the quality of the job. Furthermore, practicing safety not only protects the electrician but also safeguards the well-being of those around them, including colleagues, clients, and the general public.

Electrical Hazards

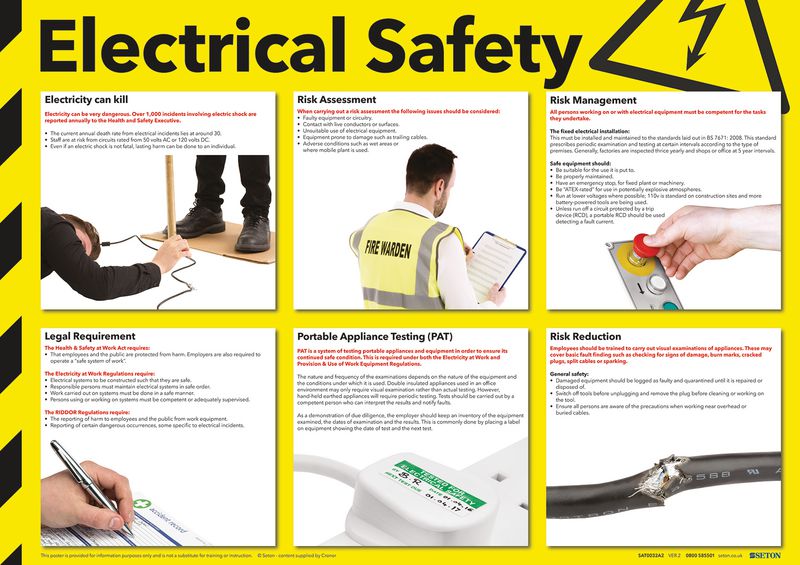

Understanding Electrical Hazards

Before delving into the details of safety practices, it is essential for electricians to have a solid understanding of electrical hazards. Electrical hazards are potential sources of danger that arise from the presence or use of electricity. These hazards can lead to electric shocks, burns, fires, explosions, and even death. Recognizing and identifying electrical hazards is crucial in preventing accidents and maintaining a safe working environment.

Types of Electrical Hazards

Several types of electrical hazards exist, each carrying its own risks. Some common types include electrical shock, arc flash, arc blast, burns, and fires. Electrical shock occurs when a person comes into contact with an electrical current, leading to potential harm or injury. Arc flash is an electric discharge that produces immense heat and light, causing severe burns. Arc blast, on the other hand, is an explosion resulting from the rapid expansion and release of the superheated air and gases during an arc fault. Burns can occur when an electrician comes into contact with overheated equipment or currents. Additionally, electrical hazards can cause fires, which can be particularly destructive and life-threatening.

Effects of Electrical Hazards

Electrical hazards can have severe and life-altering effects on individuals. Electric shock can cause muscle contractions, loss of consciousness, burns, and even lead to cardiac arrest. Arc flash and arc blast can cause severe burns, permanent scarring, blindness, and hearing damage. Burns can result in excruciating pain, disfigurement, and long-term physical and psychological trauma. Electrical fires can quickly spread, posing risks to lives and property, and may result in serious injuries or fatalities. It is crucial for electricians to understand the potential consequences of electrical hazards to reinforce the importance of following safety protocols.

Personal Protective Equipment (PPE)

Overview of Personal Protective Equipment

Personal Protective Equipment (PPE) is a crucial aspect of ensuring the safety of electricians. PPE refers to specialized clothing and equipment designed to protect against workplace hazards. In the context of electrical work, PPE serves as a barrier between the electrician and potential electrical hazards, minimizing the risk of injuries. It is important for electricians to understand the different types of PPE and their proper use to effectively safeguard themselves.

Types of Personal Protective Equipment

Several types of PPE are essential for electricians. These include safety glasses or goggles to protect the eyes from debris and potential electrical flashes, flame-resistant clothing to minimize burn injuries, rubber insulating gloves to prevent electric shock, hard hats to protect against falling objects, and safety boots with non-conductive soles to reduce the risk of electric shock. Additionally, high-visibility vests or clothing should be worn to ensure visibility in potentially hazardous environments. The use of appropriate PPE significantly reduces the likelihood of injuries and promotes a safer working environment.

Proper Use and Maintenance of PPE

While having access to PPE is important, proper use and maintenance are equally vital. Electricians should be trained on the correct use of PPE to ensure maximum effectiveness. This includes proper donning and doffing techniques, checking for any damages or defects, and ensuring a proper fit. Additionally, regular inspections and maintenance of PPE are crucial to identify and address any issues promptly. Electricians must understand that PPE is not a one-time investment but requires ongoing care and replacement when necessary to provide optimal protection.

Electrical Safety Training

Importance of Electrical Safety Training

Electrical safety training is a fundamental component of equipping electricians with the knowledge and skills to work safely. Through comprehensive training programs, electricians gain a deeper understanding of electrical hazards, safety procedures, and best practices. Electrical safety training not only helps prevent accidents and injuries but also promotes a safety-centric culture within the workplace. By being well-equipped with the necessary knowledge, electricians are empowered to make informed decisions, mitigate risks, and handle potentially hazardous situations effectively.

Topics Covered in Electrical Safety Training

Electrical safety training covers a wide range of topics to ensure comprehensive knowledge and preparedness. Topics commonly addressed include electrical hazard recognition, understanding electrical systems, proper use of PPE, safe work practices, lockout/tagout procedures, emergency response protocols, understanding electrical codes and regulations, and handling electrical incidents. Additionally, training programs may also include first aid and CPR training to ensure electricians can provide immediate assistance in case of emergencies. Training programs should be regularly updated to incorporate new information and practices.

Accessing and Participating in Training Programs

Electricians should actively seek out opportunities for electrical safety training to enhance their skills and knowledge. Training programs are often offered by employers, industry associations, and regulatory bodies. Electricians can also access online resources and tools provided by reputable organizations. It is essential for electricians to prioritize their own safety and actively participate in these training programs to stay up-to-date with best practices and ensure their own well-being and the safety of others.

Safe Work Practices

General Safe Work Practices

Adhering to safe work practices is crucial in minimizing the risks associated with electrical work. Electricians should always follow general guidelines such as wearing appropriate PPE, ensuring a clean and organized workspace, and using proper tools and equipment. It is important to avoid rushing tasks and take the time to properly plan and execute work. Additionally, communicating with colleagues and organizing work schedules can help promote a safer and more coordinated working environment.

Preventing Electrical Fires and Explosions

Electricians can play a vital role in preventing electrical fires and explosions by following specific safety practices. Regular inspection and maintenance of equipment, identifying and addressing potential hazards, and ensuring proper grounding and bonding are crucial steps in minimizing the risk of fires and explosions. Avoiding overloading circuits, using the correct wattage for light fixtures, and handling flammable materials with caution are also important preventative measures.

Working with Energized Equipment

While de-energizing equipment is highly recommended, there are instances where electricians may have to work with energized equipment. In such cases, extreme caution must be exercised, and additional safety measures should be followed. Electricians should utilize proper PPE, including flame-resistant clothing, insulating gloves, and safety glasses. Similarly, implementing lockout/tagout procedures and following step-by-step guidelines can help mitigate risks and ensure the safety of everyone involved.

Working in Confined Spaces

Electricians may often find themselves working in confined spaces, presenting unique safety challenges. Proper planning and preparation are crucial in such scenarios. Electricians should ascertain the presence of potential electrical hazards, ensure proper ventilation, and follow permit-required confined space protocols. The use of lighting equipment, communication devices, and fall protection systems can significantly enhance safety when working in confined spaces.

Working at Heights

Working at heights can be particularly dangerous for electricians, necessitating adherence to strict safety precautions. Fall protection systems, such as harnesses and anchor points, should always be utilized when working at elevated locations. Ensuring proper ladder safety, practicing safe climbing techniques, and using appropriate personal fall arrest systems are essential measures in minimizing the risk of falls and injuries.

Proper Tool Usage and Maintenance

Electricians heavily rely on a wide array of tools to perform their work effectively. Understanding how to safely and correctly use these tools is imperative for personal safety. Electricians should ensure they are using the right tool for each task, follow manufacturer’s instructions, and inspect tools for any damages or defects before use. Regular maintenance, including cleaning, lubrication, and calibration, should be performed to ensure optimal functionality. Proper storage and organization of tools can prevent accidents caused by mishandling or improper storage.

Lockout/Tagout Procedures

Importance of Lockout/Tagout Procedures

Lockout/tagout procedures are critical safety measures employed to prevent the unexpected energizing or start-up of machinery or equipment. These procedures ensure that electrical circuits are de-energized, isolated, and rendered inoperative, safeguarding the well-being of electricians during maintenance, repair, and servicing activities. Strict adherence to lockout/tagout procedures eliminates the potential for accidental energization, reducing the risk of electrocution or other injuries.

Steps to Implement Lockout/Tagout Procedures

Implementing lockout/tagout procedures involves a series of systematic steps to effectively disable electrical systems. These steps typically include:

- Preparing for shut down: Electricians must be familiar with the equipment and its energy sources, identify the isolation points, and gather the necessary tools and devices.

- Shutting down the equipment: Electricians must follow designated shutdown procedures to de-energize and isolate the equipment from its energy sources.

- Applying lockout/tagout devices: Lockout devices, such as locks or tags, are securely attached to the energy isolation devices to prevent accidental re-energization. Tags should be prominently visible and clearly indicate that the equipment is locked out.

- Release of stored energy: Electricians must ensure energy stored in capacitors, springs, or other components is safely discharged or relieved.

- Verification of isolation: The equipment’s de-energization must be validated using appropriate testing equipment to ensure the absence of electrical energy.

- Performing maintenance or repair work: Once the equipment is properly locked or tagged out, authorized personnel can proceed with their assigned tasks.

- Removing lockout/tagout devices: Only authorized personnel who completed the lockout/tagout procedure can remove the devices after ensuring it is safe to do so.

Risk Assessment and Documentation

Prior to implementing lockout/tagout procedures, a thorough risk assessment should be conducted to identify potential hazards and develop appropriate safety measures. This assessment helps determine the level of risk associated with specific machinery or equipment and aids in the establishment of proper lockout/tagout protocols. It is essential to document all lockout/tagout procedures, including equipment identification, isolation points, involved personnel, and the time and date of implementation. These records serve as valuable references for future maintenance, inspections, and training purposes.

Emergency Preparedness

Importance of Emergency Preparedness

Electricians must be prepared to handle emergencies effectively to minimize the potential consequences of unforeseen events. Emergency preparedness ensures that electricians can respond promptly, follow proper procedures, and provide necessary assistance in critical situations. Being equipped with the knowledge and skills to handle emergencies can save lives, prevent further injuries, and protect property.

Creating an Emergency Response Plan

Creating an emergency response plan is crucial for any workplace, including electricians’ work environments. The plan should outline the necessary steps to be taken in the event of various emergencies, such as electrical fires, electrical shocks, explosions, or natural disasters. It should include designated emergency exits, assembly points, emergency contact information, and a clear chain of communication. Additionally, the plan should be communicated to all personnel, regularly reviewed, and updated as needed.

Fire Safety and Extinguisher Usage

Fire safety is a vital aspect of emergency preparedness for electricians. It is essential to have a thorough understanding of the types of fires that can occur, methods of fire prevention, and the correct usage of fire extinguishers. Electricians should be trained on different types of fire extinguishers and their appropriate use for different classes of fires, such as electrical fires, chemical fires, or combustible material fires. Regular inspections and maintenance of fire extinguishers should be conducted to ensure their effectiveness in case of emergencies.

First Aid and CPR Training

Electricians should undergo first aid and CPR training to provide immediate assistance in the event of accidents or injuries. Understanding basic life-saving techniques, such as cardiopulmonary resuscitation (CPR), using automated external defibrillators (AEDs), and knowing how to control bleeding or stabilize injuries, can make a significant difference in the outcome of an emergency situation. Additionally, having access to first aid kits and being familiar with their contents is vital.

Working in Hazardous Environments

Identifying and Handling Hazardous Substances

Electricians may encounter hazardous substances while working, such as asbestos, lead, or other chemicals. It is crucial to be able to identify these substances and understand the potential risks associated with them. Following proper safety measures, such as wearing appropriate PPE, using proper ventilation, and implementing containment protocols, is necessary when working with or near hazardous substances. If exposure is suspected or confirmed, it is important to follow established procedures for reporting and getting medical attention.

Working in Confined Spaces

Working in confined spaces poses unique hazards and risks that electricians must be cognizant of. These spaces can be challenging to access, lack proper ventilation, and present dangers such as poor lighting, limited mobility, or potential entrapment. Electricians should receive proper training on confined space entry protocols, including permits, communication, monitoring, and emergency response procedures. Ensuring adequate ventilation, using appropriate safety equipment, and having emergency rescue plans in place are essential when working in confined spaces.

Working with Flammable Materials

Working with flammable materials increases the risk of fires and explosions, necessitating stringent safety practices. Electricians must be knowledgeable about the properties of flammable materials they may encounter, such as solvents, fuels, or gases, and understand safe handling, storage, and disposal procedures. The use of appropriate PPE, avoiding ignition sources, and maintaining good housekeeping practices can greatly reduce the risk of accidental fires and explosions.

Working in Wet Conditions

Working in wet conditions presents electricians with additional electrical hazards. Water increases the conductivity of electricity, making the risk of electric shock higher. Electricians should follow proper safety procedures when working in wet conditions, such as using ground fault circuit interrupters (GFCIs), ensuring proper insulation and grounding, and avoiding contact with water whenever possible. Additionally, maintaining a clean and dry workspace, using appropriate PPE, and implementing drying measures are essential to reduce the risk of accidents.

Safety Inspections and Maintenance

Importance of Regular Safety Inspections

Regular safety inspections are crucial for identifying potential hazards, maintaining a safe working environment, and complying with safety regulations. Safety inspections help ensure that electrical systems, equipment, and facilities are in proper working condition and free from defects or issues that could pose risks to electricians. By conducting routine inspections, potential hazards can be identified and addressed promptly, preventing accidents and creating a safer work environment.

Common Electrical Hazards to Inspect

During safety inspections, electricians should be vigilant in identifying common electrical hazards. These hazards may include damaged or frayed electrical cords, improperly installed or malfunctioning electrical outlets, overloaded circuits, exposed wiring, inadequate grounding, or faulty equipment. Additionally, inspections should cover emergency exits, fire safety equipment, and proper storage and handling of hazardous materials. Prompt reporting and remediation of identified hazards are essential in ensuring electrical safety.

Maintaining and Updating Safety Equipment

Maintaining and updating safety equipment is crucial in upholding a safe working environment for electricians. Equipment such as fire extinguishers, emergency lighting systems, first aid kits, and safety signage should be regularly inspected, tested, and maintained to ensure their functionality. Any damaged or expired equipment should be promptly replaced or repaired to guarantee optimal performance when needed. Following manufacturer guidelines and industry best practices for equipment maintenance is paramount.

Reporting and Documenting Safety Issues

Creating a culture of safety requires active participation and open communication. Electricians should be encouraged to report any safety concerns or incidents promptly. All reported safety issues should be documented, investigated, and addressed by qualified personnel. By documenting safety issues and resolutions, trends can be identified, and appropriate actions can be taken to prevent similar incidents in the future. This data can also be used to enhance safety training programs and implement targeted improvements in workplace safety.

Continuous Learning and Improvement

Staying Updated with Safety Standards and Regulations

The field of electrical safety is constantly evolving, with new standards, regulations, and safety practices being introduced regularly. It is essential for electricians to stay up-to-date with the latest safety standards and regulations to ensure compliance and maintain a safe working environment. Regularly reviewing industry publications, attending seminars, and participating in professional development opportunities can help electricians remain abreast of current safety practices.

Learning from Near Misses and Incidents

Near misses and incidents provide valuable opportunities for learning and improvement. Electricians should be encouraged to report and analyze near misses and incidents to identify the root causes and determine preventive measures. A thorough investigation should be conducted to understand what went wrong, why it happened, and how similar incidents can be prevented in the future. By fostering a blame-free culture and prioritizing learning from mistakes, electricians can continuously improve their safety practices.

Participating in Safety Committees and Meetings

Active participation in safety committees and meetings is another important aspect of continuous learning and improvement. Electricians should engage in safety committees to collectively identify potential hazards, develop safety protocols, and provide recommendations for improving safety practices. Regular safety meetings foster open communication, allowing for the exchange of ideas, sharing of experiences, and addressing emerging safety concerns. Through collaboration, electricians can contribute to creating a safer work environment and positively influence workplace safety culture.

In conclusion, basic safety for electricians is an essential aspect of their profession. Safety practices, such as understanding electrical hazards, utilizing personal protective equipment, undergoing electrical safety training, implementing safe work practices, following lockout/tagout procedures, being prepared for emergencies, working safely in hazardous environments, conducting safety inspections, and pursuing continuous learning and improvement, are paramount in ensuring the well-being of electricians and those around them. By prioritizing safety, electricians can carry out their work effectively, minimize the risk of accidents and injuries, and contribute to creating a safer working environment for everyone involved.

- Tags:

- Basic

- Electricians

- Understanding