If you’ve ever found yourself scratching your head when faced with an electrical issue, fear not! In this article, we will guide you through a simple and effective step-by-step process to diagnose electrical faults. Whether it’s a flickering light, a blown fuse, or a circuit breaker that keeps tripping, we’ve got you covered. By following these straightforward steps, you’ll be able to pinpoint the source of the problem and take the necessary steps to fix it. So, let’s get started on your journey to becoming an electrical fault detective!

Step 1: Understand Basic Electrical Concepts

Understanding Electrical Circuits

To diagnose electrical faults effectively, it’s crucial to have a basic understanding of electrical circuits. An electrical circuit includes a power source, such as a battery or electrical outlet, connected to various components like switches, lights, or appliances. These components are connected in a loop, allowing the flow of electricity. By understanding how electricity flows through a circuit, you’ll be better equipped to identify and fix any faults that may occur.

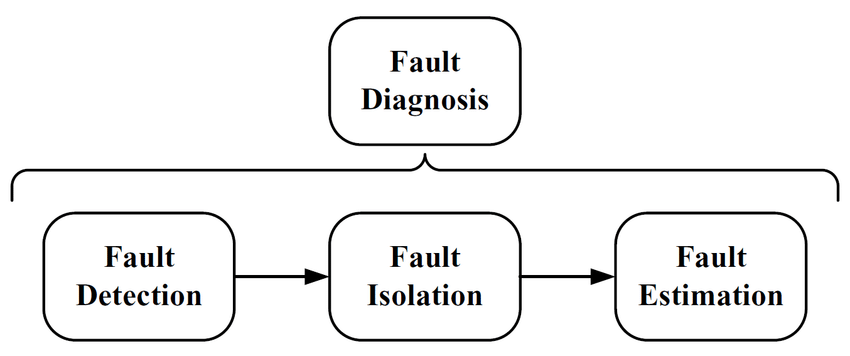

Knowing the Different Types of Electrical Faults

Electrical faults can manifest in several ways, and it’s important to be familiar with the different types to effectively diagnose them. Some common types of electrical faults include short circuits, open circuits, ground faults, and overload faults. A short circuit occurs when two or more wires with different voltages come into contact, causing excessive current flow. An open circuit is a break in the circuit that prevents the flow of electricity. Ground faults happen when the hot wire comes into contact with the grounding wire or other conductive material. Overload faults occur when the electrical load exceeds the capacity of the circuit. By understanding these different types of faults, you’ll be able to narrow down the potential issues and troubleshoot more effectively.

Step 2: Safety Precautions

Turning off the Power

Before beginning any electrical fault diagnosis, it’s essential to ensure your safety by turning off the power to the circuit you’ll be working on. Locate the circuit breaker or fuse box and switch off the corresponding circuit breaker or remove the fuse. This step will prevent any accidental electric shocks or equipment damage while you diagnose the fault.

Using Personal Protective Equipment (PPE)

While diagnosing electrical faults, it’s vital to protect yourself with appropriate personal protective equipment (PPE). PPE includes items such as insulated gloves, safety goggles, and non-conductive footwear. Insulated gloves provide a barrier between your hands and the electrical current, while safety goggles protect your eyes from potential sparks or flying debris. Wearing non-conductive footwear ensures that you are not creating a path for electric current through your body. By wearing the necessary PPE, you greatly reduce the risk of injury during the diagnostic process.

Step 3: Gathering Necessary Tools and Equipment

Multimeter

A multimeter is an essential tool for diagnosing electrical faults. It can measure various electrical properties, including voltage, current, and resistance. By using a multimeter, you can test the electrical flow, identify potential issues, and determine if components are functioning correctly or not.

Circuit Tester

A circuit tester is a useful tool for identifying live wires and detecting electrical presence. It typically consists of a probe that you can insert into outlets or touch against wires to determine if electricity is flowing. This tool is particularly handy when checking if power is reaching a specific point in the circuit.

Voltage Detector

Similar to a circuit tester, a voltage detector helps you identify the presence of voltage in wires or other electrical components. It provides a quick and safe method of checking for voltage without the need for physical contact. Voltage detectors are invaluable when working with live circuits, as they ensure your safety and help pinpoint faulty connections.

Insulation Resistance Tester

An insulation resistance tester enables you to assess the quality of insulation on wires. It measures the resistance of the insulation material and helps identify any weaknesses or faults. This tool is especially important when inspecting older electrical systems or when you suspect insulation damage.

Voltage Stabilizer

A voltage stabilizer is an automated device that regulates and stabilizes the voltage level in electrical circuits. It ensures a consistent and reliable power supply, preventing damage to sensitive electrical equipment and appliances. While not essential for fault diagnosis, having a voltage stabilizer can help ensure accurate test results and reliable electrical readings.

Step 4: Visual Inspection

Checking for Visible Damage or Loose Connections

Performing a visual inspection is an essential aspect of electrical fault diagnosis. Inspect the electrical components, wiring, and connections for any visible damage or signs of wear. Look for loose connections, frayed wires, melted insulation, or any other abnormalities. These visual cues can provide valuable information about potential faults or areas that require further investigation.

Inspecting Wire Insulation

During your visual inspection, pay close attention to the insulation covering the wires. Insulation helps prevent the flow of electricity to unintended paths and protects against electrical shocks. Look for any cracks, cuts, or exposed wires, as these could lead to short circuits or other faults. If you notice any issues with the wire insulation, mark it for further testing or replacement.

Step 5: Testing the Power Supply

Verifying Power Supply Voltage

To diagnose electrical faults accurately, it’s essential to verify the voltage level of the power supply. Use a multimeter set to the appropriate voltage range to measure the voltage at various points in the circuit. Compare the measured voltage values with the expected voltage levels to identify any deviations that may indicate a faulty power supply.

Checking Circuit Breakers and Fuses

Faulty or tripped circuit breakers and blown fuses can often be the cause of electrical faults. Inspect the circuit breakers and fuses to identify any visually observable issues, such as a tripped switch or a blown fuse. Use a circuit tester to test whether the circuit breaker or fuse is functioning correctly. If a circuit breaker trips frequently or a fuse repeatedly blows, it indicates a deeper underlying issue that requires further investigation.

Step 6: Testing for Short Circuits

Using a Multimeter to Check for Shorts

Short circuits can disrupt the electrical flow and potentially cause damage. To test for short circuits, set your multimeter to the resistance mode and ensure that the circuit is not powered. Disconnect any components or wires suspected of causing the short circuit and touch the multimeter probes at both ends of the circuit. A reading close to zero resistance indicates a short circuit that needs to be resolved.

Isolating the Short Circuit

Once you have identified a short circuit, the next step is to isolate it. Start by disconnecting the circuit from its power source. If the short circuit persists, examine the wiring and components along the circuit for any visible signs of damage or contact between wires. By systematically isolating and inspecting each section of the circuit, you can locate the specific area responsible for the short circuit and make the necessary repairs.

Step 7: Testing for Open Circuits

Using a Multimeter to Check for Opens

Open circuits occur when there is a break in the electrical flow, preventing electricity from reaching its intended destination. To test for open circuits, set your multimeter to the continuity mode and ensure the circuit is not powered. Touch the multimeter probes at different points along the circuit, checking for continuity. An open circuit will show no continuity, indicating a break in the circuit.

Locating the Open Circuit

Finding the break in an open circuit can be a bit more challenging than identifying a short circuit. Start by examining the wires and connections along the circuit for any visible breaks or loose connections. Twist or move the wires gently to detect any intermittent connectivity issues. If necessary, use an insulation resistance tester to identify the exact location of the break. Once located, repair or replace the damaged section of the circuit to restore electrical flow.

Step 8: Troubleshooting Ground Faults

Locating Faulty Ground Connections

Ground faults can cause electrical shocks and pose serious safety hazards. To troubleshoot ground faults, examine all ground connections in the circuit for looseness or signs of damage. Check the grounding wire and connections for any frayed insulation or corrosion. Make sure the connections are tight and secure. If you suspect a ground fault but cannot locate the issue visually, using a voltage detector can help identify any stray voltage present.

Testing Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters (GFCIs) are specialized outlets designed to protect against ground faults. If you suspect a ground fault, test any GFCIs in the circuit. Press the “test” button on the GFCI outlet to simulate a ground fault. If the GFCI trips and cuts off the power, it indicates that the GFCI is functioning correctly. However, if the GFCI does not trip, it suggests a faulty GFCI that needs replacement. Properly functioning GFCIs are crucial for maintaining electrical safety in areas such as kitchens, bathrooms, and outdoor outlets.

Step 9: Identifying Overload Faults

Calculating Current Load

Overload faults occur when the electrical load exceeds the circuit’s capacity, leading to overheating and potential damage. To identify overload faults, calculate the current load on the circuit by adding up the individual current draw of all connected devices. Consult the devices’ specifications or use a current clamp meter to measure the current flow. Compare the calculated load with the circuit’s maximum capacity to determine if there is an overload issue.

Checking for Overloaded Circuits

Inspect the circuit’s wiring and connections for any signs of overheating or excessive heat. Overloaded circuits can cause wires to become hot and even melt insulation. If you notice any visually observable signs of overheating, such as discoloration or a burning smell, it indicates an overload fault. In such cases, consider redistributing the load or adding a new circuit to accommodate the electrical demand properly.

Step 10: Professional Assistance

Knowing When to Call an Electrician

While many electrical faults can be diagnosed and resolved by homeowners, there are situations where professional assistance is crucial. If you encounter complex electrical systems, are unsure about your diagnosis, or lack the necessary skills and knowledge, it’s best to call a licensed electrician. Electrical work can be dangerous, and attempting repairs beyond your expertise may lead to further damage or accidents. Recognize your limits and seek professional help when needed to ensure safety and the proper resolution of electrical faults.

Diagnosing electrical faults can be a challenging task, but by following these step-by-step guidelines and taking the necessary precautions, you can effectively troubleshoot and resolve various electrical issues. Remember, safety should always be the priority, so if you are unsure or uncomfortable, it’s best to seek the assistance of a professional electrician.