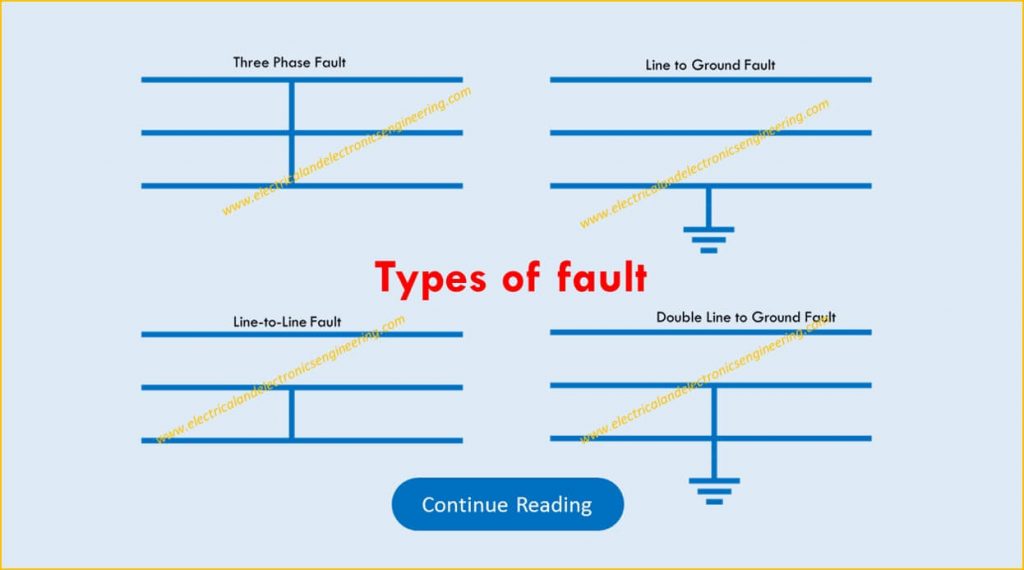

In the world of electrical systems, there are two types of electrical faults that can occur: open faults and short faults. An open fault occurs when there is a break in the electrical circuit, resulting in a discontinuity of current flow. On the other hand, a short fault happens when there is an unintended connection between two points in a circuit, causing an abnormal increase in current flow. Understanding these types of electrical faults is crucial in diagnosing and troubleshooting issues in electrical systems. Let’s dive into a deeper exploration of these faults and learn how to identify and address them effectively.

Short Circuit

Definition

A short circuit refers to an electrical malfunction that occurs when a current bypasses its intended path and takes a shortcut, resulting in a low-resistance connection between two points in the circuit. This creates excessive current flow, potentially leading to overheating, equipment damage, or even fire.

Causes

Short circuits can occur due to various reasons, such as damaged insulation, faulty wiring, loose connections, or accidental contact between live wires. Additionally, equipment failure or manufacturing defects can also contribute to short circuits.

Effects

The effects of a short circuit can be severe and pose significant risks, ranging from electrical shocks to fires. Excessive current flow generates heat, which can result in the melting or burning of insulation, nearby materials, or even electrical components. This can not only cause damage to the circuit itself but also endanger the safety of individuals in proximity.

Prevention

To prevent short circuits, it is essential to ensure proper installation and regular maintenance of electrical systems. Proper insulation, secure wiring connections, and the use of circuit breakers or fuses are crucial in preventing short circuits. Additionally, avoiding overloading circuits and being cautious while using electrical equipment can significantly reduce the risk of short circuits.

Open Circuit

Definition

An open circuit refers to an electrical circuit where the current flow is interrupted due to a break in the circuit’s pathway. Unlike a short circuit, an open circuit lacks a complete and continuous pathway for current to travel, resulting in the absence of flow.

Causes

open circuits can occur due to various reasons, such as broken wires, disconnected plugs, switches in the off position, or blown fuses. Additionally, environmental factors, such as corrosion or physical damage to the wiring, can also lead to open circuits.

Effects

The effects of an open circuit can vary depending on the specific situation or application. In most cases, an open circuit prevents the operation of electrical devices, rendering them useless or non-functional. Additionally, open circuits can result in power loss, interruption in electrical supply, or the inability to transmit signals.

Prevention

To prevent open circuits, it is crucial to regularly inspect and maintain electrical connections, ensuring they are secure and in good condition. Promptly addressing any signs of damage, such as frayed wires or loose connections, can significantly reduce the likelihood of open circuits. Additionally, utilizing surge protectors and ensuring proper installation of electrical devices can help prevent open circuit situations.

Ground Fault

Definition

A ground fault occurs when an electrical current finds an unintended path to the ground, bypassing the normal circuit. This can result from a break in the insulation or a short circuit between a current-carrying conductor and the grounding system.

Causes

Ground faults can be caused by factors such as damaged wiring, faulty electrical equipment, moisture intrusion, or inadequate grounding. It can also occur due to human error, such as incorrect installation or improper use of electrical devices.

Effects

Ground faults can pose serious risks, including electrical shock hazards and the potential for electrocution. Additionally, ground faults can lead to equipment damage, power outages, or fire hazards, especially if the fault occurs in critical electrical systems.

Prevention

To prevent ground faults, proper grounding and insulation techniques are essential. Regular inspection and maintenance of electrical systems, along with the use of ground fault circuit interrupters (GFCIs), can help detect and protect against ground faults. Additionally, following proper electrical installation guidelines and ensuring proper training for personnel working with electrical systems can help prevent ground fault-related incidents.

Overload

Definition

Overload refers to a situation where an electrical circuit is subjected to more current flow than it is designed to handle. This can occur when there are too many electrical devices or appliances connected to a single circuit or when a power-hungry device draws excessive current.

Causes

Overload can be caused by factors such as plugging multiple high-wattage devices into a single outlet, using extension cords or power strips beyond their capacity, or operating equipment that draws excessive power. Additionally, outdated or inadequate electrical wiring systems can contribute to overload situations.

Effects

Overload situations can lead to overheating of wires and electrical components, posing a significant fire hazard. The excess current can result in circuit breakers tripping or fuses blowing, interrupting the power supply and potentially causing damage to electrical devices. In severe cases, overloaded circuits can cause electrical fires.

Prevention

To prevent overload situations, it is crucial to distribute electrical loads evenly across multiple circuits. Avoiding the excessive use of extension cords or power strips and ensuring proper wiring capacity for high-power devices can help prevent overloads. Regularly checking the load rating of circuits and circuit breakers and avoiding the use of multiple high-wattage devices simultaneously can also contribute to preventing overloads.

Arc Fault

Definition

An arc fault refers to an abnormal electrical discharge or sparking that occurs when current jumps across a gap between two conductors. It commonly happens when there is a loose or damaged wire connection or a breakdown in insulation, allowing the current to escape its intended path.

Causes

Arc faults can be caused by various factors, including damaged insulation, loose or corroded wiring connections, overheating, rodents chewing on wires, or physical damage to cables or cords. Improper installation techniques and using incorrect or incompatible components can also contribute to arc faults.

Effects

Arc faults can generate intense heat and emit sparks, potentially igniting nearby combustible materials and leading to electrical fires. The high temperatures and flames produced by arc faults can cause significant damage to electrical systems, equipment, and infrastructure. Moreover, arc faults can result in power outages, interruptions in electrical supply, and the risk of injury or loss of life.

Prevention

Preventing arc faults involves implementing proper installation practices, such as securely connecting wires and ensuring accurate insulation. Regular inspection and maintenance of electrical systems can help promptly identify and address loose connections or damaged insulation. Additionally, utilizing arc fault circuit interrupters (AFCIs) can detect and disconnect circuits experiencing arc faults, significantly reducing the risk of fire or other damage.

Undervoltage

Definition

Undervoltage, also known as voltage sag or low voltage, refers to a decrease in the supplied electrical voltage below normal levels. It can occur due to various reasons, such as faults in the power grid, heavy loads drawing excessive current, or issues in the distribution system.

Causes

Undervoltage can be caused by factors such as power grid malfunctions, severe weather conditions, heavy equipment starting up and causing voltage drops, or voltage regulation issues in the electrical distribution system. Additionally, inadequate wiring or undersized transformers can contribute to undervoltage situations.

Effects

Undervoltage can result in reduced efficiency and performance of electrical devices and equipment. It can cause flickering lights, decreased motor speed, overheating of electrical components, and potential damage to sensitive electronic devices. Undervoltage can also affect the overall reliability of electrical systems and may lead to sudden power outages or failures.

Prevention

Preventing undervoltage requires proactive measures, such as proper design and sizing of electrical systems, including transformers and wiring. Installing voltage regulators or automatic voltage regulators (AVRs) can help maintain voltage levels within the desired range, compensating for fluctuating power supply. Regular monitoring of electrical voltages and quick intervention in case of undervoltage incidents are essential to minimize the impact and prevent equipment damage.

Overvoltage

Definition

Overvoltage occurs when the supplied electrical voltage exceeds the normal or standard levels. This can result from external factors, such as lightning strikes, power surges, or faults in the power grid, or internal factors, such as equipment malfunction or incorrect voltage selection.

Causes

Overvoltage can be caused by lightning strikes, faulty power grid operations or equipment, switching operations, or the sudden removal of heavy loads. Additionally, incorrect voltage selection or malfunctioning voltage regulators can also lead to overvoltage situations.

Effects

Overvoltage can cause severe damage to electrical devices, equipment, and sensitive electronic components. Excessive voltage can result in overheating, shortening the lifespan of equipment and causing failures. It can also lead to sparks, arcing, or fire hazards, posing significant safety risks. Moreover, overvoltage can cause power supply disruptions and result in downtime or interruptions in critical operations.

Prevention

Preventing overvoltage involves the installation of surge protection devices (SPDs) to divert excessive voltage spikes away from electrical systems and equipment. Regular maintenance and inspection of electrical systems can help identify and address potential overvoltage risks, such as faulty equipment or damaged wiring. Additionally, selecting appropriate voltage levels, employing stable voltage regulators, and implementing proper grounding techniques can assist in preventing overvoltage incidents.

Phase Imbalance

Definition

Phase imbalance refers to an inequitable distribution of currents or voltages across the individual phases of a three-phase electrical system. It occurs when the current or voltage levels in any of the phases deviate significantly from the desired or expected values.

Causes

Phase imbalance can be caused by factors such as unbalanced loads, mismatched equipment or components, improper wiring, or faulty connections. It can also result from uneven distribution of single-phase loads in a three-phase system or poor phase sequence connections.

Effects

Phase imbalance can lead to disproportionate sharing of currents among phases, causing overheating and excessive stress on specific components within the electrical system. This can result in decreased efficiency, increased energy consumption, and potential damage or premature failure of motors, transformers, or other equipment. Additionally, phase imbalance can affect the stability and reliability of electrical systems and contribute to power quality issues.

Prevention

Preventing phase imbalance involves proper design and installation of three-phase electrical systems, ensuring balanced loads across all phases. Regular inspection and maintenance can help identify and rectify any imbalances in equipment or connections. Employing equipment with built-in monitoring and protection systems can also aid in preventing adverse effects caused by phase imbalances.

Motor Fault

Definition

A motor fault refers to any abnormality or malfunction that occurs within an electric motor, limiting its performance or causing it to cease functioning entirely. Motor faults can be mechanical, electrical, or a combination of both, and they can affect the motor’s operation or lead to complete motor failure.

Causes

Motor faults can be caused by factors such as overloads, inadequate lubrication, misalignment, excessive temperature, bearing wear, manufacturing defects, or electrical issues like short circuits or phase imbalances. External factors such as dust, moisture, or environmental conditions can also contribute to motor faults.

Effects

Motor faults can result in reduced motor efficiency, decreased torque output, increased energy consumption, or overheating. Faulty or malfunctioning motors can cause unplanned downtime, interrupting critical operations and leading to productivity losses. Additionally, motor faults can cause increased maintenance and repair costs, and in severe cases, may require motor replacement.

Prevention

Preventing motor faults requires regular inspection, maintenance, and preventive measures. Proper motor installation, including correct alignment, lubrication, and cooling, can help minimize the risk of faults. Routine checks of electrical connections, insulation tests, and complying with recommended operating conditions can also prevent motor faults. Employing motor protection devices such as thermal overload relays, voltage monitoring devices, or condition monitoring tools can aid in early fault detection and prevention.

Earth Fault

Definition

An earth fault, also known as a ground fault, occurs when a live conductor comes into contact with a conductive part that is connected to the earth. This can result in the diversion of current through the unintended path to the ground, bypassing the normal circuit.

Causes

Earth faults can be caused by various factors, such as insulation breakdown, damaged cables, faulty equipment, or incorrect wiring connections. It can also occur due to accidental contact with conductive materials, such as water or metallic objects, which can lead to electrical leakage.

Effects

Earth faults pose significant safety risks, as they can lead to electrical shock hazards and possible electrocution. Additionally, earth faults can cause electrical equipment to malfunction or trip protective devices, resulting in power outages or interruptions. In certain scenarios, earth faults can generate heat and spark, leading to fires or explosions.

Prevention

To prevent earth faults, it is crucial to ensure proper grounding and insulation of electrical systems. Regular checks for damaged or deteriorated insulation, loose connections, or exposed conductive parts can help mitigate the risk of earth faults. Employing residual current devices (RCDs) or ground fault circuit interrupters (GFCIs) can instantly detect and disconnect earth fault currents, providing an additional layer of protection. Additionally, promoting electrical safety awareness and providing adequate training for individuals working with electrical systems can contribute to preventing earth fault incidents.

In conclusion, understanding and addressing different types of electrical faults is vital for ensuring the safety and reliability of electrical systems. Taking preventive measures, such as proper installation, regular maintenance, and the use of protective devices, can significantly reduce the risks associated with these faults. By prioritizing electrical safety practices and staying vigilant, you can help prevent potential hazards, protect valuable equipment, and maintain efficient operation of electrical systems.

- Tags:

- Electrical

- Explained

- Faults