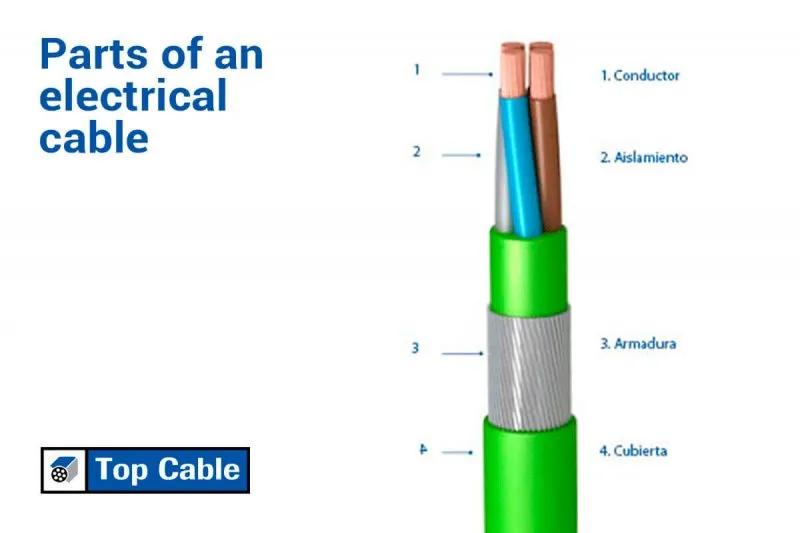

In this article, we will take a closer look at the three crucial components that make up a domestic wiring cable. Understanding these parts is essential for safely and efficiently managing electrical connections in our homes. So, let’s dive in and explore how conductors, insulation, and sheathing work together to keep our electrical systems running smoothly.

Insulation

Definition

Insulation is a crucial component of domestic wiring cables that provides electrical insulation and protection. It is a non-conductive material that surrounds the conductors of the cable, preventing the flow of electrical current to external surfaces or other conductors.

Function

The primary function of insulation in a domestic wiring cable is to ensure the safety of the electrical system and the individuals using it. It prevents electrical leakage, short circuits, and the risk of electric shock. Insulation also helps in maintaining the integrity of the electrical signals and minimizing signal degradation.

Materials Used

Various materials are used for insulation in domestic wiring cables. Some common materials include polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), and thermoplastic elastomers (TPE). The choice of insulation material depends on factors such as voltage rating, temperature range, and environmental conditions.

Conductor

Definition

The conductor is a vital part of a domestic wiring cable that carries the electrical current. It is typically made of copper or aluminum, as these materials offer excellent electrical conductivity.

Function

The main function of the conductor is to allow the flow of electricity from the power source to the connected electrical devices. It serves as a pathway for the electrical current, ensuring efficient transmission without significant power loss.

Types of Conductors

There are two primary types of conductors used in domestic wiring cables: solid conductors and stranded conductors. Solid conductors consist of a single wire and are typically used for in-wall installations. Stranded conductors, on the other hand, are made up of multiple thin strands of wire twisted together, providing flexibility and ease of installation.

Sheath

Definition

The sheath, also known as the outer jacket, is the protective covering of a domestic wiring cable. It encloses the insulation and conductors, providing mechanical strength, durability, and protection against environmental factors.

Function

The main function of the sheath is to protect the inner components of the cable from physical damage, moisture, chemicals, and other external elements. It acts as a barrier between the cable and its surroundings, ensuring the longevity and safe operation of the electrical system.

Types of Sheaths

Different types of sheaths are used in domestic wiring cables based on specific applications and environmental conditions. Common types include PVC (Polyvinyl Chloride), LSZH (Low Smoke Zero Halogen), and TPE (Thermoplastic Elastomer). The choice of sheath material depends on factors such as fire resistance, flexibility, and environmental regulations.

Insulation Resistance

Importance

Insulation resistance is a critical characteristic of domestic wiring cables. It measures the ability of the insulation material to resist the flow of current through it. High insulation resistance ensures the safety and reliability of the electrical system.

Testing

Insulation resistance can be tested using a Megger insulation tester. This test involves applying a high DC voltage between the conductor and the sheath and measuring the resulting current flow. The insulation resistance is then calculated using Ohm’s law.

Factors Affecting

Several factors can affect the insulation resistance of a domestic wiring cable. Some common factors include temperature, humidity, insulation material quality, and aging. Understanding these factors and regular testing is essential to maintain proper insulation resistance for a safe electrical system.

Voltage Rating

Definition

Voltage rating refers to the maximum voltage at which a domestic wiring cable can safely operate. It indicates the insulation’s capability to withstand the electrical voltage present in the system without breakdown or leakage.

Determining Factors

The voltage rating of a domestic wiring cable depends on factors such as the insulation material, insulation thickness, and the intended application. Higher voltage ratings are required for industrial or commercial settings where higher voltages are involved.

Importance

Choosing the appropriate voltage rating is crucial to ensure the safety and performance of the electrical system. Using a cable with a voltage rating lower than the system’s voltage can result in insulation failure, electrical leakage, and potential hazards.

Current Carrying Capacity

Definition

Current carrying capacity refers to the maximum amount of electrical current that a domestic wiring cable can support without exceeding its temperature rating and causing damage.

Factors Determining

The current carrying capacity of a cable depends on various factors, including the conductor material, size, insulation type, ambient temperature, and installation method. Proper consideration of these factors is essential to avoid overheating and potential fire hazards.

Calculation

The current carrying capacity can be calculated based on industry standards and guidelines, taking into account the cable’s cross-sectional area, ambient temperature, and installation conditions. It is crucial to consult relevant codes and regulations to ensure safe and efficient electrical installations.

Temperature Rating

Definition

Temperature rating refers to the maximum temperature that a domestic wiring cable can withstand without degrading its performance or causing damage.

Determining Factors

Several factors determine the temperature rating of a cable, including the insulation material, conductor size, and ambient temperature. Different insulation materials have varying resistance to heat, and their temperature ratings need to be considered for appropriate cable selection.

Safety Considerations

Choosing a cable with a temperature rating suitable for the intended application is crucial for safety. Operating a cable above its temperature rating can lead to insulation failure, breakdown, and potential fire hazards. It is essential to adhere to the recommended temperature limits and follow proper installation practices.

Flexibility

Importance

Flexibility is an essential characteristic of domestic wiring cables, especially when routing them through confined spaces or around corners. A flexible cable allows for easier installation, reduces strain on the wires, and provides greater convenience during maintenance or upgrades.

Factors Affecting

Several factors can affect the flexibility of a cable, such as the type of conductor (solid or stranded), insulation material, and overall construction. Stranded conductors offer greater flexibility compared to solid conductors. Additionally, the choice of insulation material and its thickness can impact the cable’s flexibility.

Applications

Flexible domestic wiring cables find extensive use in residential and commercial installations where the ability to bend and maneuver the cable is necessary. They are commonly used in applications such as lighting fixtures, power outlets, appliances, and data communications.

Durability

Importance

Durability is a critical factor in domestic wiring cables as they are expected to provide long-lasting performance in various environments. A durable cable minimizes the risk of premature failure, reduces maintenance requirements, and ensures the continued operation of the electrical system.

Factors Affecting

Several factors can affect the durability of a cable, including the choice of materials, construction quality, environmental conditions, and mechanical stress during installation. Poor-quality materials or improper installation practices can compromise the cable’s durability, leading to issues such as insulation degradation, conductor damage, or sheath wear.

Maintenance

Regular inspection and maintenance are important to ensure the durability of domestic wiring cables. Periodic checks for signs of wear, damage, or degradation, along with adherence to manufacturer guidelines, can help identify and address potential issues before they escalate.

Safety Considerations

Fire Resistance

Fire resistance is a crucial safety consideration for domestic wiring cables. Certain cables are specifically designed with fire-resistant properties, such as LSZH (Low Smoke Zero Halogen) sheaths, which minimize the release of toxic smoke and harmful chemicals in the event of a fire. Choosing fire-resistant cables can greatly enhance the safety of the electrical system and occupants.

Electrical Shock

Preventing electrical shock is paramount when it comes to domestic wiring cables. Proper insulation, grounding, and adherence to electrical codes and regulations play a significant role in minimizing the risk of electrical shock. Regular testing and inspection of the insulation resistance are essential to ensure its effectiveness in preventing electrical leakage.

Installation Guidelines

Proper installation is crucial for the safe and efficient operation of domestic wiring cables. Following installation guidelines and industry standards is essential to prevent issues such as incorrect wiring connections, inadequate insulation, or improper cable support. It is recommended to consult professional electricians or adhere to recognized installation practices to ensure the utmost safety during the installation process.

In summary, understanding the three parts of a domestic wiring cable – insulation, conductor, and sheath – is essential for safe and reliable electrical installations. Factors such as insulation resistance, voltage rating, current carrying capacity, temperature rating, flexibility, durability, and safety considerations should be carefully considered to ensure the longevity and performance of the electrical system.

- Tags:

- cable

- Domestic Wiring

- Three Parts